Andrew Gomarsall MBE, executive director, n2s

Tech-driven applications and business models continue to grow exponentially. And so does the resultant environmental impact of a vast and growing IT footprint, from the superpowered hyperscale facilities hosting public clouds to enterprise facilities, whether on-premises or colocation. The appetite for yet more IT hardware assets can only continue to accelerate with 5G communications technology, artificial intelligence/machine Learning and the Internet of Things.

However, delivering a net zero solution out of nowhere is daunting.

Project managers need to ask technology vendors how they are planning sustainable tech solutions for the future. Though IT and network equipment and cabling are becoming more energy efficient, most of the carbon footprint comes ‘ready wrapped’ on final product delivery to users – before powering up. In fact, 70-90 percent of it. This is the ‘embodied’ carbon expended across the supply chain, from the sourcing of raw materials, component assembly through to product manufacture.

The data centre industry is already making huge strides in the race to net zero. Through more energy efficient buildings, infrastructure and cooling, and renewable power including on-site generation of solar and wind energy. But there is still much more to be done when it comes to maximising the sustainability of their or their customers’ IT assets – from PCs, laptops, servers and storage hardware to network routers and copper-based cabling. Tech manufacturers, enterprise businesses, data centre operators and service providers need to be implementing Zero Waste strategies which optimise equipment lifetimes to reduce overall embodied carbon levels.

A circular economy

A circular economy only occurs when resources are kept in use for as long as possible, maximum value is extracted while in use, and materials are sustainably recovered and regenerated at the end of their useful life. Unfortunately, today, it is still very much a linear ‘one-way street’ economy when it comes to electrical and electronic equipment in general, including enterprise and data centre IT assets. The default setting of rip, dispose and replace every few years is driving up the exponential volumes of e-waste year on year. In 2022 this was estimated in the UN’s Global E-waste Monitor to be at a record 62m tonnes.

All of this serves to underline the critical importance of doing everything possible to reclaim and redress the balance in the equipment usage and post-usage phases. The latter is where most of the opportunity lies: By extending typical three to five years product lifetimes through licensed and regulated refurbishment, reselling and reuse. It can add perhaps a further five years.

Crucially, when beyond useful repair, only ethical and sustainable asset disposal should be carried out by licensed and accredited WEE operators. Materials recovered such as gold, copper and steel can then go back into manufacturing streams and once again become part of the technology manufacturing process, completely closing the lifecycle loop, or they can be reformed, becoming anything from street furniture to traffic cones. This circular technology solution offers the most secure, sustainable way for enterprise and industry to realise their ESG commitments.

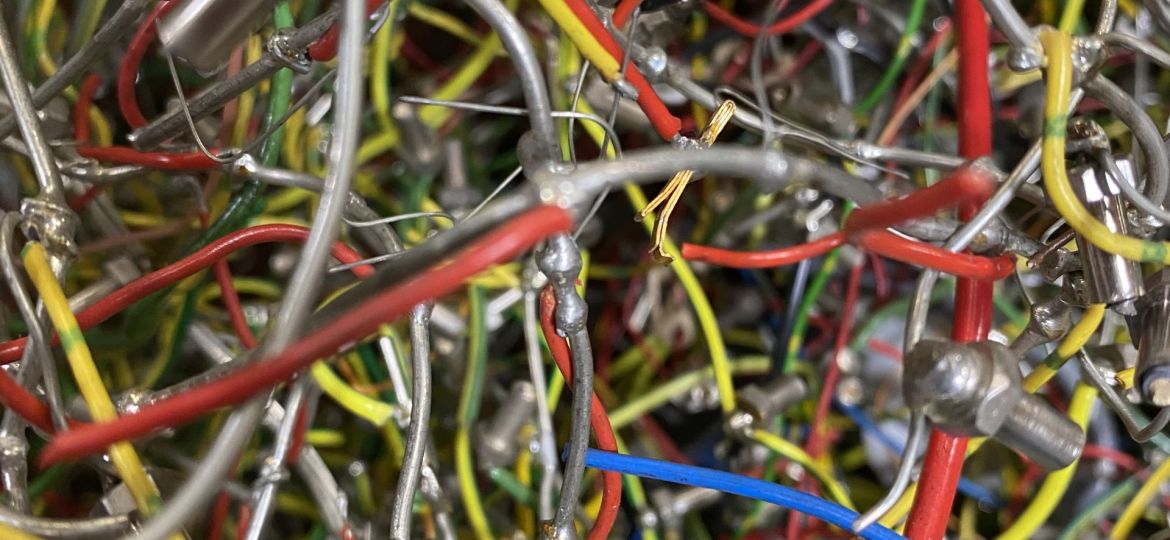

PCB metals recovery

A key success factor is implementing a scalable and totally sustainable method of extraction and recovery of PCB-based precious metals. Bioleaching is emerging as a potentially game changing solution and one that n2s has pioneered and our sister company, Bioscope Technologies, is now developing at scale. Naturally occurring bacteria are used to leach out the metal content, allowing PCB materials to be reclaimed, conserved and recycled without use of harmful acids.

PCBs can contain up to 60 precious metals including gold, silver, platinum, copper and palladium. Many of the materials used are in increasingly limited supply, or hard to access and are lost due to ritual processes with a detrimental effect to our planet. The irony is, a circular economy would drive better quality yields of material, for example, recycling one tonne of PCB boards can contain 40 to 800 times more gold – and 30 to 40 times more copper – than can be mined from one tonne of ore.

Throughout the technology lifecycle, environmental impact reporting is a vital part of keeping energy usage and emissions on track.

For example, a dashboard demonstrating how an organisation is contributing to UN Sustainable Development Goals by reporting data on the weight and volumes of technology re-used, re-sold and recycled; Science-based metrics provide data on environmental impacts around savings and sustainability which can be visualised and converted into actionable information.

In summary, a truly circular IT economy is key to effective reduction of both embodied C02e in IT asset manufacture and the growing mountain of e-waste. To maximise sustainability, more enterprise businesses, data centre operators and IT service providers need to act now by implementing zero-waste strategies.